What is Machine Vision?

Definition and Importance of Machine Vision

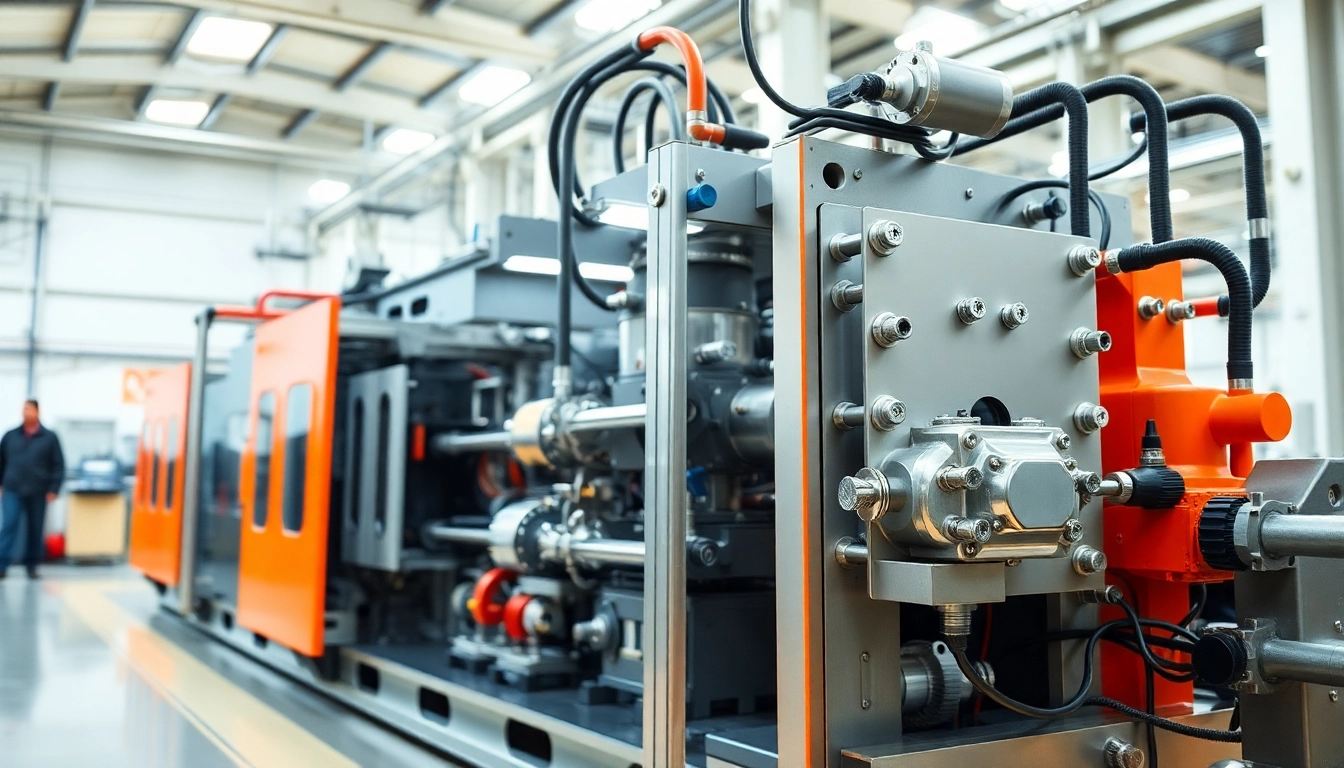

Machine vision refers to the technology and methodologies that enable machines to process and interpret visual data, much like human vision. It encompasses a variety of systems that use cameras and other imaging devices to automatically inspect products, guide robots, and recognize objects. This robust technology has transformed various industries by increasing efficiency, accuracy, and reliability in automation. The significance of machine vision is evident in its ability to enhance quality control, optimize processes, and support complex decision-making processes in real-time.

Components of Machine Vision Systems

Machine vision systems comprise several integral components that work harmoniously to achieve their objectives. These components include:

- Cameras: Cameras capture visual data. They can be of various types, such as line scan or area scan cameras, depending on the application.

- Lighting: Proper lighting conditions are crucial for image clarity and contrast. Different types of lighting (backlight, front light, etc.) are selected based on the products being inspected.

- Image Processing Software: This software allows for the analysis of acquired images. It can include algorithms for detecting defects, measuring dimensions, and making decisions based on predefined criteria.

- Computing Hardware: The images and data processed require powerful computing systems for real-time analysis and decision-making.

- Output Devices: Often used for feedback and communication, output devices relay information regarding the inspection results to operators or controlling systems.

Applications Across Industries

Machine vision has widespread applications across diverse sectors, including:

- Manufacturing: Used for quality control, assembly verification, and product sorting, helping to reduce waste and improve efficiency.

- Automotive: Enhances processes like inspection of components, welding, painting, and assembly line guidance.

- Pharmaceutical: Ensures product integrity by tracking packaging, verifying labels, and conducting dose counting.

- Food and Beverage: Monitors product quality, verifies packaging, and ensures compliance with safety regulations.

- Logistics and Warehousing: Utilized for barcode scanning, product identification, and automated sorting systems.

How Machine Vision Works

Image Acquisition Techniques

The first step in machine vision is image acquisition. This process involves capturing images using various techniques, such as:

- Traditional Cameras: Standard industrial cameras that use CCD or CMOS sensors to capture images.

- Line Scan Technology: Particularly effective in monitoring continuous processes, line scan cameras capture images one line at a time.

- 3D Imaging: Involves the use of laser triangulation or structured light to create three-dimensional representations of objects, beneficial for dimensional inspection.

- Multispectral Imaging: Captures images across multiple wavelengths, enabling more detailed analysis of products, particularly in agricultural and food applications.

Processing and Analysis of Visual Data

Once images are captured, the subsequent step is processing them to extract useful information. This can involve:

- Image Enhancement: Techniques such as filtering, contrast adjustment, and thresholding improve image quality for better analysis.

- Feature Extraction: Utilizing algorithms to identify relevant features, such as edges, shapes, or colors, crucial for determining product quality.

- Pattern Recognition: Deep learning methods allow for advanced recognition of complex patterns and objects, essential in environments requiring high accuracy.

Hardware and Software Integration

Effective machine vision systems require seamless integration of hardware and software components. Hardware like cameras, lights, and processing units must be compatible and optimized to work with software algorithms designed for specific applications. This involves:

- Compatibility: Selecting hardware that matches the software requirements to ensure efficient communication and data transfer.

- Calibration: Regular calibration ensures that the system maintains accuracy over time by compensating for environmental variations.

- User Interface: User-friendly software interfaces facilitate easier operation and adjustments, particularly in industries with rapid production lines.

Comparing Machine Vision and Computer Vision

Key Differences Explained

While both machine vision and computer vision involve processing visual data, they serve different purposes and functionalities:

- Machine Vision: Primarily focused on automating visual inspections and decisions in controlled industrial environments.

- Computer Vision: More general technology used in various applications, including medical imaging, autonomous vehicles, and real-time surveillance.

Applications of Each Technology

The applications of machine vision are typically limited to industrial scenarios while computer vision spans broader applications, including:

- Machine Vision: Used in production lines for quality control, sorting, and assembly guidance.

- Computer Vision: Applied in facial recognition, image classification, and action recognition in complex environments.

Impact on Industrial Automation

Both technologies enhance automation capabilities significantly, but machine vision tends to have a more immediate impact on efficiency and accuracy in manufacturing processes. By reducing human error and providing real-time insights, machine vision plays a critical role in maintaining high standards of product quality and operational excellence.

Challenges in Implementing Machine Vision

Common Obstacles and Solutions

Implementing machine vision can come with challenges that require careful consideration:

- Lighting Conditions: Inconsistent lighting can adversely affect image quality. Solutions include optimizing lighting setups and adapting algorithms that account for variable conditions.

- Complex Environments: Cluttered workspaces can lead to false positives. Implementing robust filtering techniques and advanced algorithms can mitigate these issues.

- System Integration: Ensuring that all components function well together can be complicated. Collaboration between hardware and software vendors can lead to better integrated solutions.

Cost Considerations and Budgeting

The initial setup cost of machine vision systems can be substantial due to their complexity. It’s vital for businesses to:

- Conduct a Cost-Benefit Analysis: Analyze potential savings from reduced errors and increased efficiency against the initial investment.

- Invest in Scalable Solutions: Opt for systems that can grow with the business needs to avoid frequent upgrades.

- Consider Long-Term Savings: Factor in the savings from reduced labor and increased output over time to justify upfront costs.

Technical Limitations and How to Overcome Them

Technical limitations, such as resolution and processing speed, can hinder performance. Addressing these includes:

- Upgrading Hardware: Investing in high-resolution cameras and faster processing units can enhance performance.

- Modernizing Software: Keeping software up-to-date with the latest algorithms improves analysis speed and accuracy.

- Training Personnel: Ensuring that operators are familiar with the technology can mitigate misunderstanding and misuse.

The Future of Machine Vision Technology

Emerging Trends and Innovations

Technological advancements are continuously reshaping machine vision, with several key trends emerging:

- Integration with AI: Machine learning algorithms are increasingly being incorporated into machine vision systems, allowing for smarter analysis and improved accuracy.

- Miniaturization: Smaller vision systems are becoming more common, allowing for applications in confined spaces or mobile environments.

- Internet of Things (IoT) Integration: IoT connectivity enables machine vision systems to gather and share data in real time, enhancing operational insights and decision-making.

Impact of AI and Machine Learning

The adoption of AI and machine learning is revolutionizing machine vision by enabling systems to learn from data over time. This empowers machines to identify new patterns and anomalies beyond predefined rules, leading to better quality assurance and predictive maintenance.

Potential Market Growth and Opportunities

The future of machine vision appears promising, with expected growth across industries driven by increased investments in automation and smart technologies. As industries continue to adopt IoT and AI technologies, opportunities will arise for innovation in machine vision solutions, making it a significant area for investment and development.

Leave a Reply